Part 1 of our 3 Part Series:

Get a firsthand look at Land Cruiser 100 Series Problems. Gain valuable insights and practical solutions to common problems.

- I. Introduction

- II. Toyota Land Cruiser 100 Problems we faced before the shakedown trip

- Corroded Starter Connector: Overcoming a Morning Hitch

- Ongoing Alarms: Corroded Door Sensor/Contact

- The Tale of a Failing Rear Diff Lock Actuator

- Rear Right Axle Shaft and Wheel Bearing: An Unsettling Click

- Shock Absorber Close Call: The Critical Importance of Routine Checks

- Broken Wheel Stud: An Unspectacular Yet Crucial Lesson

- Cylinder Head Cover Gasket Leakage: A Self-Inflicted Oversight

- III. After the shakedown trip: New Land Cruiser 100 Problems

- IV. West Africa Charity Expedition: Unveiling More Land Cruiser 100 Series Challenges

I. Introduction

The Toyota 100 Series Land Cruiser, celebrated for its rugged prowess, captivates enthusiasts globally. In this article, we explore our real-life encounters, navigating the fine line between completing the Land Cruiser 100 rebuild and embracing daily utility. Challenges unveil insights into age-related issues and the consequences of human errors.

Having covered 50,000 kilometers, somewhat strictly adhering to the maintenance schedule, our experiences provide tangible accounts of the vehicle’s resilience. Moments where components „rattled loose“ showcase nuanced challenges in prolonged usage.

With 10,000 km of Expedition Conditions: Land Cruiser 100 Series Problems

Driving through diverse terrains and different continents, we’ve encountered only a small spectrum of issues. From age-induced intricacies to the aftermath of human errors, each challenge offers valuable lessons. Funny enough, most of them happened at home.

Age-Induced Complexities

Time inevitably leaves its mark. Our Land Cruiser 100 Series, weathering the years, presented challenges echoing its aging components.

Human Errors and Ramifications

Despite the pursuit of perfection, it led to unequivocal errors. This section sheds light on such missteps and their consequential impact.

Rattled Loose: Wear and Tear Chronicles

Wear and tear, an inevitable companion on extended journeys, manifests in unexpected ways. We dissect instances, offering insights into the endurance and vulnerabilities of our Land Cruiser 100 or any other overlanding vehicle for that matter.

In subsequent sections, we delve into the granular details of each of our Land Cruiser’s problems, providing not only glimpses into our experiences but also practical solutions for fellow Land Cruiser 100 enthusiasts. This list of our Land Cruiser 100 Series problems offers a unique perspective on the challenges that can accompany owning this iconic vehicle.

II. Toyota Land Cruiser 100 Problems we faced before the shakedown trip

Corroded Starter Connector: Overcoming a Morning Hitch

One spring morning, with plans set for the day, we found ourselves thwarted by a familiar click and the engine refusing to start. Concerns about the aging starter with an odometer reading of 380,000km loomed. Rather than jumping to conclusions, I popped the hood and meticulously checked all connections to and from the starter. Unplugging and plugging connectors, and wiggling bolts and studs, I embarked on a thorough inspection. A subsequent attempt at starting proved successful. However, when the issue resurfaced a few days later, I delved deeper. Employing abrasive fleece on bolted connections and plug pins, followed by a coat of dielectric grease known for its hydrophobic and protective qualities. This preventative measure, applied to various plugs during the rebuild, proved effective in keeping moisture and water out. Since then, the specter of starter problems in our Toyota 100 Series has become a thing of the past.

Ongoing Alarms: Corroded Door Sensor/Contact

In the realm of Toyota 100 Series issues, an unexpected symphony of alarms became a known occurrence, often triggered in the vicinity of other Toyotas without apparent cause. One evening, amidst a crowded parking lot, our alarm persisted, mysteriously ceasing upon departure. On a quieter night, without neighboring vehicles, the alarm was persistent. My reluctance to address it immediately led to an open car for the night.

The next day, the dashboard hinted at a more mundane culprit—an open door warning light. Initially suspected of being a potential cable break, it turned out to be just another corroded pin. Armed with abrasive fleece and dielectric grease, I treated all four door contacts. A straightforward preventive measure to keep the issue in our Land Crusier 100 from recurring for that reason.

The Tale of a Failing Rear Diff Lock Actuator

When acquiring what I dubbed the remnants of a Land Cruiser 100 in 2019, the Rear Diff Lock Actuator performed seamlessly. However, the tale took a turn in 2021 during offroad training maneuvers. To my dismay, it failed to engage.

Later closer inspection revealed the toll of 18 years, exposed to the elements but seldom utilized. The prognosis was grim, leaving no room for salvage. Nevertheless, I reassembled and reinstalled it for the impending winter, aware it wouldn’t see any action.

A new actuator was procured before the next spring’s inaugural shakedown trip, ensuring our Toyota 100 Series would once again navigate challenging terrains with optimal functionality.

Rear Right Axle Shaft and Wheel Bearing: An Unsettling Click

Amidst the hum of the Autobahn, a soft metallic clicking emerged from the rear right, its rhythm synchronized with tire revolutions—a subtle anomaly noticed over time. Suspecting the wheel bearing, we embarked on a diagnosis. Upon axle shaft removal for wheel bearing replacement, a disheartening revelation awaited us. The shop, tasked with the bearing exchange, uncovered prior damage to the axle shaft, presumably incurred during a previous wheel bearing replacement. A costly setback, considering the price of axle shafts. The extent of the damage remains uncertain, and the dilemma persists—whether the axle shaft warranted a full replacement or not, remains a question mark in our roster of Land Cruiser 100 Series problems.

Shock Absorber Close Call: The Critical Importance of Routine Checks

During a post-700km cruise inspection in Germany, a shocking discovery unfolded— the front shock absorber’s main screw had ventured 90% out of the mounting bracket, the nut nowhere in sight. This revelation wasn’t part of a purposeful check but a stroke of luck while investigating other matters that day. While it could have resulted in a catastrophic failure, it served as a crucial lesson on the paramount importance of regularly inspecting major components. This incident underscored the significance of not only initial checks but also the necessity of revisiting and retightening components recently worked on—a preventive measure crucial in averting potential Land Cruiser 100 Series problems.

Broken Wheel Stud: An Unspectacular Yet Crucial Lesson

In the grand tapestry of Toyota Land Cruiser issues, this incident may seem unspectacular, but its impact reverberated in our approach to tire maintenance. When transitioning from 265/75R16 Cooper Discoverer AT3 to 285/75R16 BF Goodrich AT2, a routine tire shop visit turned sour. A simple task—to loosen lug nuts—resulted in a broken wheel stud. The lesson learned was clear: take charge before leaving your vehicle at a tire shop, loosening them yourself, as negligence may prevail. Our Land Cruiser 100 left with new tires but also with a broken wheel stud, as they didn’t care. This experience prompted us to keep spare wheel studs readily available in our kits, a small yet impactful measure in maintaining our Land Cruiser’s integrity.

This article will explain why we updated our tires and what we consider to be the best tire for a Land Cruiser 100 overall: LINK

Cylinder Head Cover Gasket Leakage: A Self-Inflicted Oversight

In the saga ofLand Cruiser 100 Series problems, accountability rests solely on my shoulders for this incident. Just before embarking on a shake-down trip through the Spanish Pyrenees, I performed an oil change but inadvertently overfilled by about 0.3-0.5L. As we ascended the first steep hill, smoke billowed from the engine bay, carrying the scent of burnt oil. The excessive oil, under heightened pressure, seeped through the cylinder head cover gasket, cascading onto the exhaust manifold’s heat shield. Since then, a slight leakage persisted—a consequence of a preventable error. Despite its ease of repair, this remains a stark reminder of the importance of meticulous attention during routine maintenance, marking it as one of our Land Cruiser 100 Series problems that stems from a regrettable oversight.

III. After the shakedown trip: New Land Cruiser 100 Problems

Turbo Failure: A Lesson in Thorough Troubleshooting

In our journey with the 100 Series Land Cruiser, a seemingly minor oversight led to a crucial lesson—meticulous retracing of steps during troubleshooting is paramount. Post-replacing the Cylinder Head Gasket Cover, the Turbo remained dormant. A small yet critical vacuum hose, left disconnected, was the elusive culprit. Retracing our path uncovered the oversight, and upon reconnecting the hose, the Turbo roared back to life seamlessly. This incident underscores the significance of attention to detail and systematic diagnostics in resolving Land Cruiser 100 Series problems, even those as seemingly minor as a disconnected hose can have a substantial impact on the vehicle’s performance.

Rattled Loose:The Stealthy Disappearance of Power Steering Pump Bolts

Enduring a lingering power steering fluid leak, my quest for the source felt like an eternity. Beyond underbody fluid traces and transient pump noises, the culprit eluded me. Initial suspicions centered on a porous hose, yet fixing it yielded no respite. Determined, I delved into the power steering pump intricacies and discovered an astonishing revelation—both mounting bolts were missing, a consequence of unforeseen rattling during a shakedown trip. Amidst the vast reserve of spare nuts, a quick fix ensued.

This episode underscored the robustness of Toyota Land Cruisers, renowned for resilience despite occasional problems. It serves as a testament to their reputation for reliability, even in suboptimal conditions due to lackluster maintenance. Another explanation for the poor state of many of the old 100 Series Land Cruisers available on the market.

This experience solidified my practice of stocking extra nuts, bolts, and small hardware, a rule highlighted in my spare parts article, ensuring readiness for unforeseen Land Cruiser 100 Series problems. More on that in my article about spare parts: HERE

Enduring CV and Steering Boot Challenges: A Continuous Odyssey

The genesis of our Land Cruiser 100 Problems traces back to the Toyota workshop’s replacement of the lower and upper control arms in the front of our 100 Series. Further entrusting them with the installation of a new genuine Toyota Boot Kit for the CV axles, little did I anticipate the strenous journey that awaited us.

Shortly after rectifying the axle geometry, a torn steering boot emerged. A prompt replacement, however, unraveled a new issue—leaking CV boots. Which then were serviced and resealed by the prior Toyota workshop under warranty. The saga persisted as once more loose boots coincided with an unsettling disparity in the front suspension height—101cm (40”) on one side and 96cm (38”) on the other. A prompt correction and another free-of-charge boot fix ensued.

Still the odyssey persisted with another torn steering boot. This time, we installed a Poly-Pro bushing kit for the steering rack to ensure the issue wasn’t from a loose steering rack. Although effective in the short term, the CV boots tore again, leading to the use and probable abuse of two aftermarket repair kits before pinpointing the actual issue.

Ball Joint Removal Tool

- needed to replace the steering boot

- removing the tie rod ends

- can be used for other ball joints as well

Universal Split CV Boot

- Great to keep as an emergency repair kit

- can be used without removing the CV axle

The Long Awaited Relief: Setting the Front Suspension Right

Thorough research revealed the rubber of the CV boots „rubbing“ on itself due to an excessive angle in the CV axle. This angle, in turn, resulted from an elevated front suspension – 96cm (38”) proved too much. Looking back, we could have recognized this earlier, considering the noted stiffness/hardness of the front suspension. Ultimately, 92cm (36″) proved to be the sweet spot.

In preparation for the West Africa expedition, we opted for a complete change of the CV axles. Experimenting with the cheapest aftermarket axles in Europe, spending less than on another Toyota CV Boot Kit, we also changed the front axle flanges. This not only reduced axle play but also addressed the notorious “clunk” sometimes present in older Land Cruisers. The result? A significantly smoother ride with no more CV/steering boot issues since. This concludes another chapter of our Land Cruiser 100 Series problems.

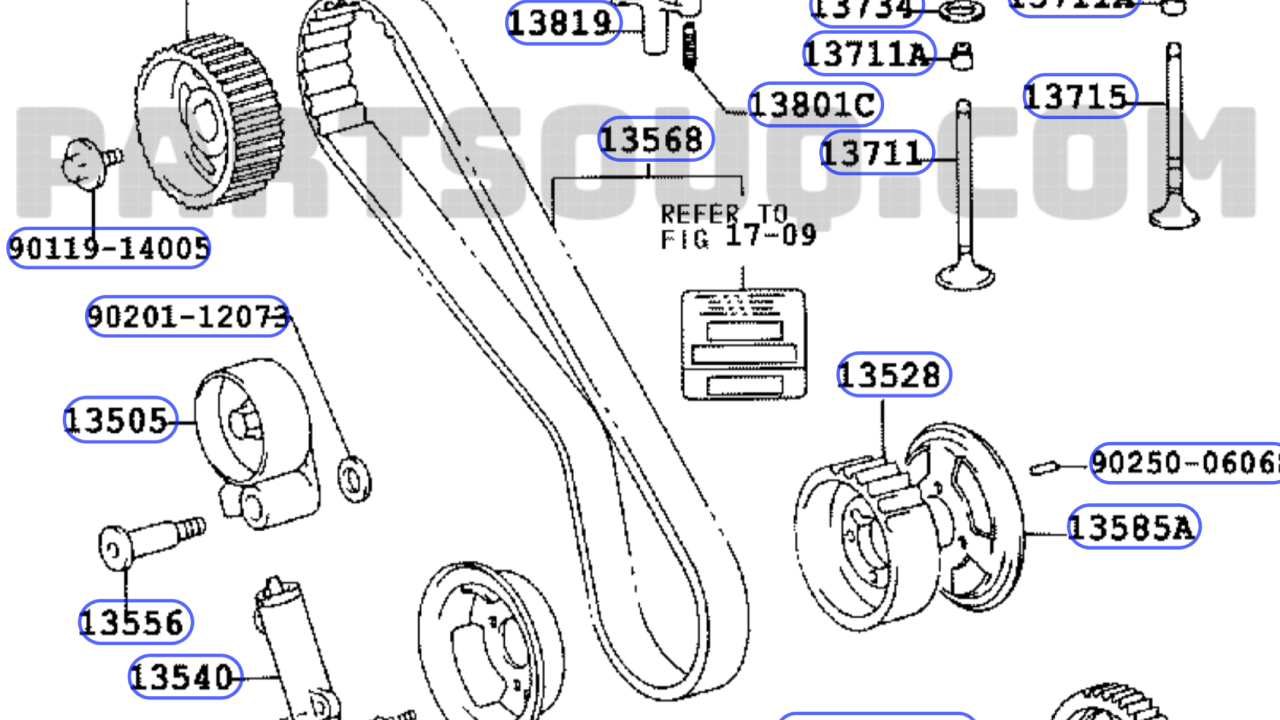

Injector Line Dilemma: Tracing the Elusive Leak in a Land Cruiser 100

During our Land Cruiser 100 rebuild, we diligently replaced the injector lines as recommended at 150,000km intervals. These vital components link the electronically controlled mechanical fuel pump to the fuel injectors. Due to their intricate positioning and shape, tightening them proves challenging. In a prior incident, a loose line resulted in a rapid fuel discharge, we could promptly resolve through re-tightening.

However, the recent 100 Series issue proved more elusive. Despite a persistent smell of diesel and minor fuel seepage, identifying the problem was difficult. Initial checks focused on the injector pipes at the injection pump, yet the problem endured. A thorough examination of the fuel system, including the tank, pump, filter, and connections, revealed no anomalies. Even preemptive clamp replacements proved futile.

The breakthrough came from a strong push on the gas pedal with a keen eye and a torch. Only under close scrutiny did we detect a fine mist emanating from one injector pipe connection. Partially concealed by the Cylinder Head Cover, visibility was challenging, explaining why leaks weren’t immediately evident. The almost unnoticably stain on the hood liner became a vital clue, leading us to address the issue effectively.

IV. West Africa Charity Expedition: Unveiling More Land Cruiser 100 Series Challenges

Embarking on our West Africa Charity Expedition, our Land Cruiser faced a new realm of challenges. Navigating diverse terrains, extreme conditions, and logistical hurdles, we encountered a fresh set of Land Cruiser 100 Series problems. From the unforgiving landscapes to the demands of off-road exploration, each kilometer brought forth unique trials. In this upcoming segment, we delve into the intricacies of our West Africa journey, shedding light on the trials faced by both vehicle and crew. From unforeseen mechanical hiccups to strategic problem-solving, the expedition revealed the resilience of the Land Cruiser 100 in the face of diverse and demanding conditions. Stay tuned for an insightful exploration of our expedition’s trials and triumphs.

Don’t miss the update, get signed up for our Newsletter now!